TEST FACILITIES

A suite of versatile test facilities is available to meet a wide range of client development and test requirements. The test facilities are often adapted to meet particular requirements and bespoke rigs are also designed and built if necessary. The facilities are grouped around several technology themes:

- Air flow

- Thermal engineering

- Structural testing

- Rotating machinery

- Engines and vehicles

Wind Energy

Whirling Arm Rain Erosion Test Rig

The ETC rain erosion test facility has recently been upgraded to improve its operating envelope and is now capable of striking test samples with water droplets at up to 150 m/s with water droplets between 1.8 mm and 2.5 mm in diameter, in controllable increments of 0.1 mm.

The test rig is highly characterised with data for droplet sizing, droplet rates, strike rates and strike locations on the test sample, making the test rig ideally suited to cutting-edge research where high levels of control and repeatability are essential.

Wind Tunnel

Energy Technology Centre's wind tunnel facility was developed and built primarily for small wind turbine development. The facility has been used for many projects developing a wide range of small wind turbine products including conventional horizontal axis wind turbines, novel ducted wind turbines and vertical axis Savonius rotors. Key performance characteristics are:

Working section: 3.2 m x 3.2 m

Maximum wind speed: 17 m/s

Fan power: 200 kW

This versatile facility is complete with essential supporting infrastructure including power analysers, resistor load banks, wind speed measurement and load measurement.

A range of fans and blowers is also available for flow system testing.

Thermal Engineering

4 MW Steam System

The Energy Technology Centre steam system comprises 2 x 2 MW steam generators, delivering steam throughout the laboratories for test and development projects. The system can deliver:

Power: 4 MW

Pressure: 30 bar

Steam mass flow: 6 tonne/h

Used mainly by a client for the development of steam screw expanders for energy recovery in industrial applications, this capability is available to clients with a requirement for testing thermal systems.

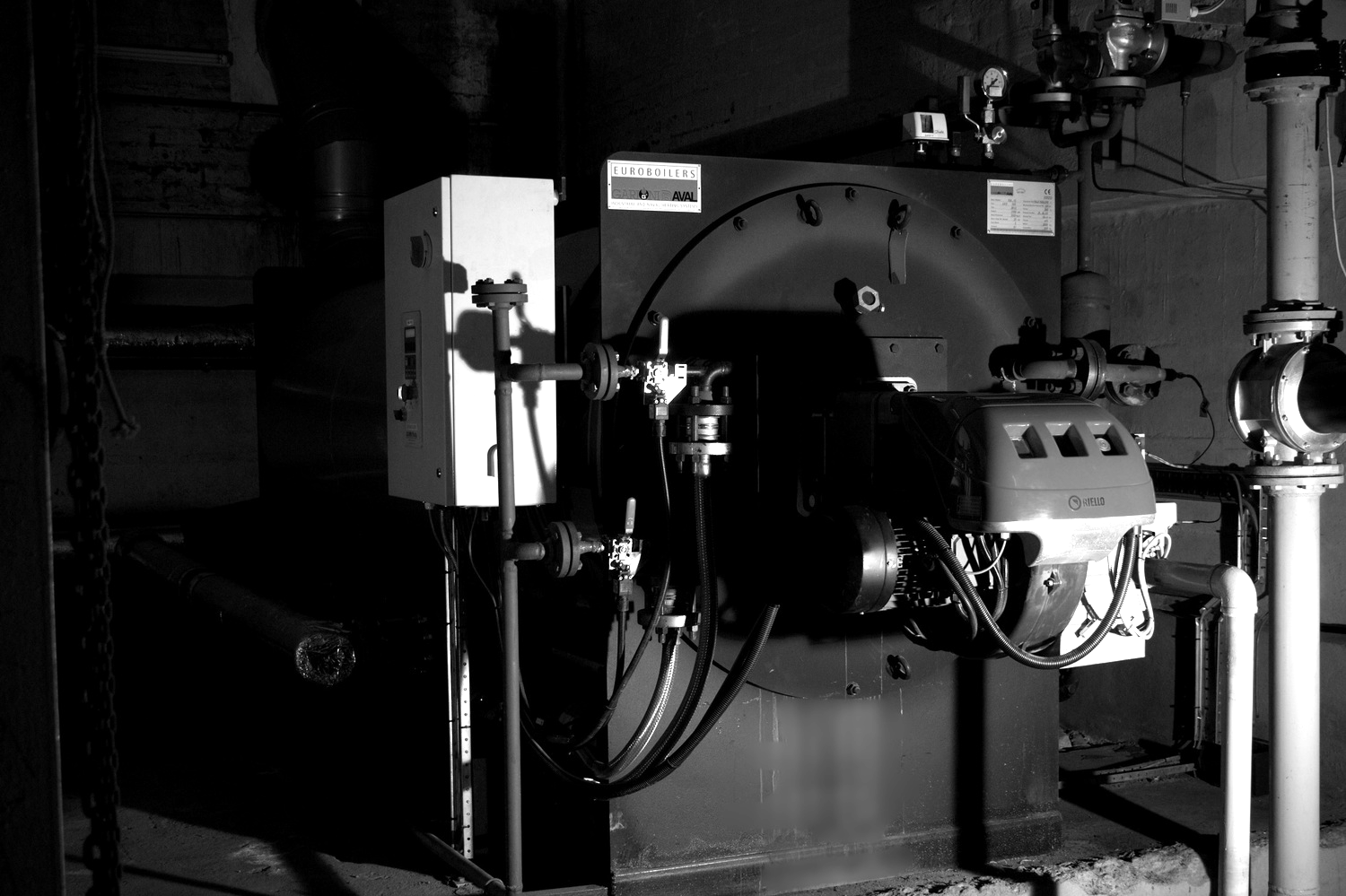

60 kW Research Boiler

A small steam boiler is available at Energy Technology Centre's facilities for research and development of burner technologies and new fuels. The boiler specifications are as follows:

Power: 30-60 kW

Pressure: 10 bar

The research boiler can be adapted to meet client requirements and is supported by measurement capability for test programmes.

Gas Turbine

Energy Technology Centre's gas turbine is available for research and development of fuels and associated technologies.

Other assets include a small scale gasifier and burner test capability.

Energy Technology Centre's thermal facilities are served by a 2.7 MW cooling system.

Structural Testing

Structural Test Laboratory

The structural testing laboratory is a versatile facility with a range of key assets for mechanical testing at system and subsystem level.

Hydraulic power pack: 170 kW (expandable)

Range of actuators: up to 2 m stroke

Hydraulic shaker table: 500 mm stroke, 50 Hz

Electrodynamic shaker tables

The laboratory and hardware can be configured to meet a wide range of client requirements. Past project have included linear generator testing of marine energy devices, component testing for novel multi-megawatt drivetrain systems and fatigue testing of marine energy components.

Rotating Machinery

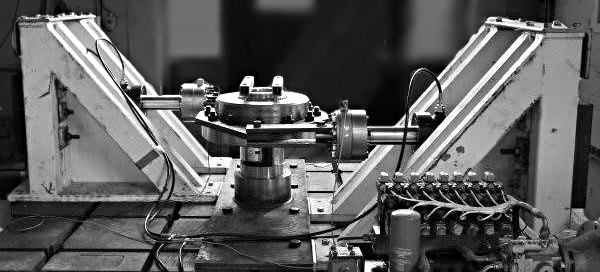

Drivetrain Test Facility

Energy Technology Centre's drivetrain test facility is a highly configurable and flexible test rig for testing multiple drivetrain components including gearboxes, chains, bearings and generators from across all sectors. Current capability:

Motor drive power: 75 kW or 110 kW

Input drive speeds: up to 6,000 r/min

Drive torque: up to 350 Nm (expandable with gearbox)

Dynamometer power: 130 kW

Dynamometer speed: up to 10,000 r/min

A wide range of further assets is available to the drivetrain facility including dynamometers and gearboxes to achieve a larger operating envelope.

The drivetrain facility is supported with high quality measurement and data acquisition systems for electrical and mechanical power, loads and related performance data. Supporting infrastructure is installed to absorb up to 285 kW electric power.

Motoring Dynamometer

The motoring dynamometer test rig is ideally suited for testing and development of small scale rotating machinery, e.g. performance characterisation of small wind turbine generators. Capability:

Power: 7.5 kW

Speed: 1,500 r/min

Torque: 50 Nm

Engines and Vehicles

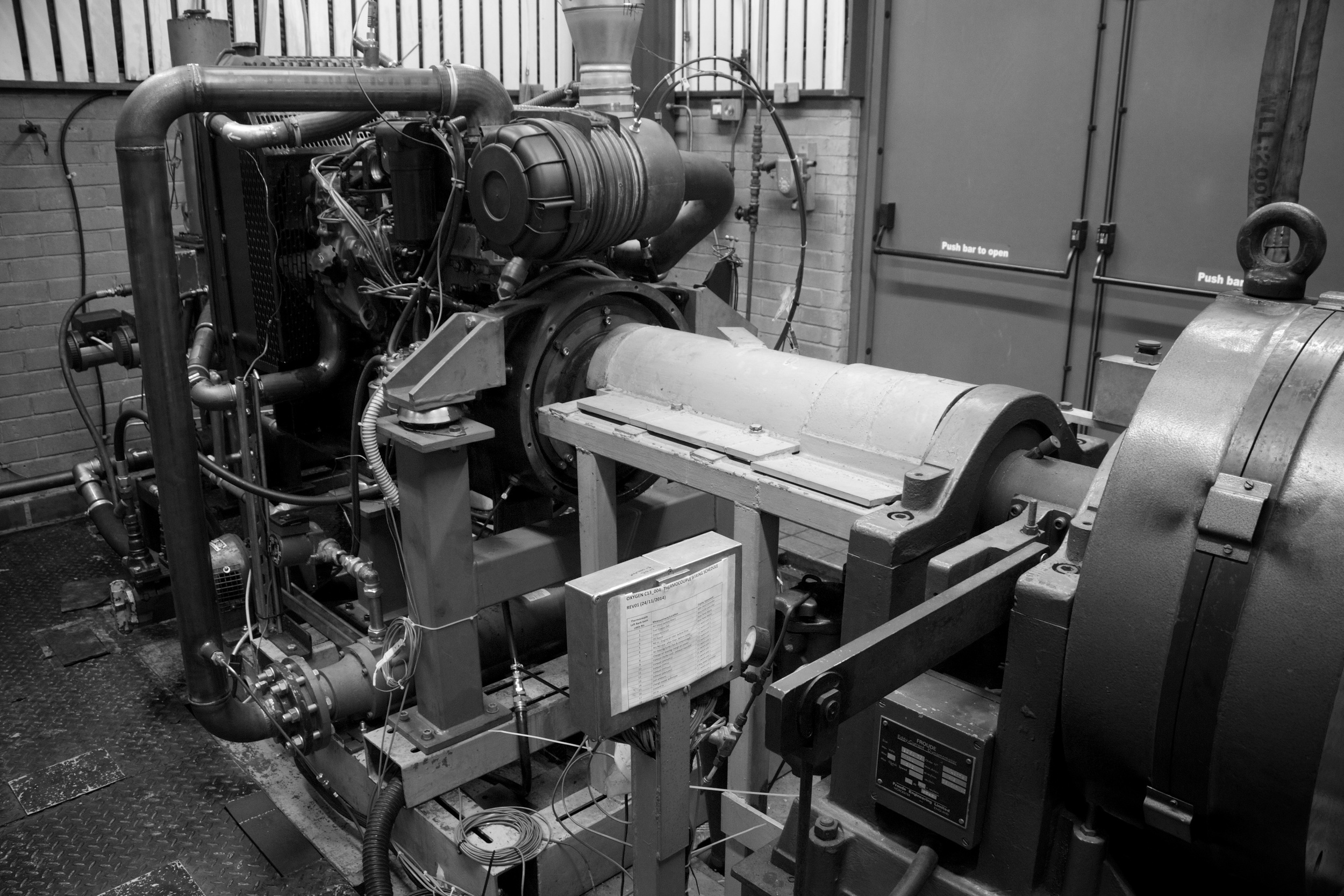

Engine Test Cells

Energy Technology Centre facilities have three engine test cells capable of running internal combustion engines, electrical drivetrains and other rotating machinery.

These are primarily used to test new fuels, fuel additives, combustion modifiers and emissions treatment devices on a wide range of combustion systems. A range of petrol and diesel engines, in addition to the gas turbine, are retained by Energy Technology Centre for assessment of new hardware and fuels.

The engine test cells have dynamometers and emissions equipment for test programmes.

Rolling Road

A rolling road facility is available primarily for the development and testing of low carbon vehicles. Key performance capabilities are:

Maximum speed: 160 km/h

Power: 168 kW

The rolling road is an ideal facility for early-stage vehicle development and assessment of alternative fuel and propulsion technologies.

Versatile Test Capability

In addition to installed facilities and infrastructure, Energy Technology Centre has several laboratory areas that can be customised to meet client testing requirements. Energy Technology Centre regularly undertakes the design, build, commissioning and operation of bespoke test rigs and facilities for clients with specific needs.

Bespoke test rigs for clients are supported by the ETC infrastructure, and measurement systems at our facility providing a comprehensive test capability. Underpinning infrastructure includes:

4 MW Steam generation

2.7 MW Cooling capability

10 bar Research boiler

170 kW Hydraulic power and range of actuators

Loads measurement up to 450 kN

Torque measurement

800 A Grid connection

Electrical power measurement

Range of electric motors from 1 kW to 110 kW

Dynamometers from 20 kW to 650 kW

Range of IC Engines

Data acquisition capability